what is vibrating screen?how does a vibrating screen work?

what is vibrating screen?how does a vibrating screen work?

Blog Article

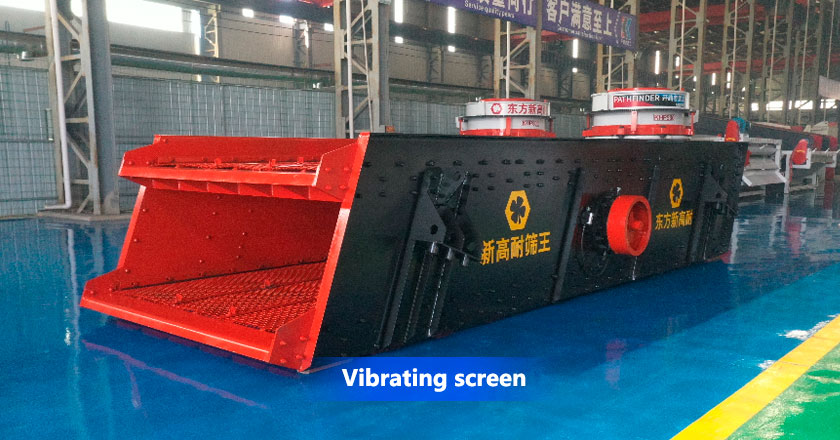

What is a vibrating screen?

Vibrating screen is a screening equipment widely used in mining, metallurgy, coal, building materials and other industries. It separates materials of different particle sizes by vibration, and is usually used for grading and screening of liquid or solid particles. The working principle of the vibrating screen is to make the material do parabolic motion on the surface of the screen through the strong vibration generated by the vibrating motor or vibrator, and separate materials of different particle sizes through the screen.

There are many types of vibrating screens according to different structural forms and working principles. Common ones include circular vibrating screens, linear vibrating screens, circular vibrating screens, etc. They can be selected according to the required screening accuracy, processing capacity, working environment, etc.

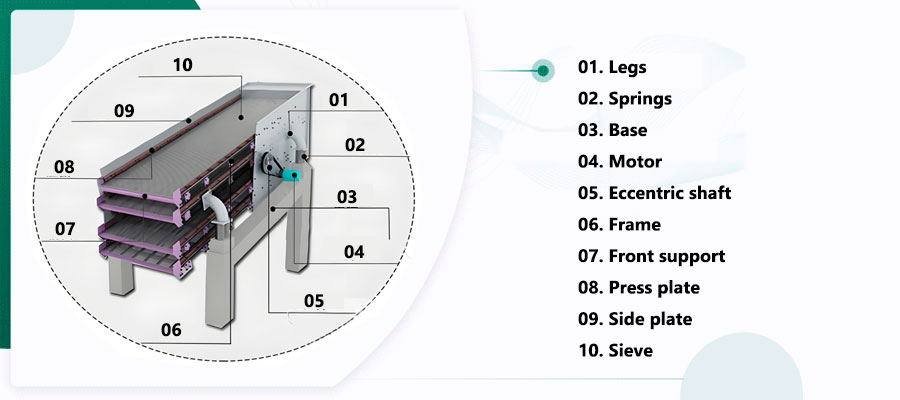

Composition structure of vibrating screen

The vibrating screen is mainly composed of a screen box, a vibrator, a support device, a transmission device, a base, a feed port and a discharge port, a screen, a sealing device, a control system, etc.

How does the vibrating screen work?

The working principle of the vibrating screen is based on the action of vibration force. Through vibration, the material is made to jump, roll and other movements on the screen, thereby realizing the screening and grading process. The specific working process is as follows:

Vibration generation: The motor drives the vibrator through the transmission device, and an eccentric motor is usually used as the vibration source. The rotor of the motor is equipped with an eccentric block. When the motor is running, the eccentric block generates centrifugal force, which drives the screen to vibrate. There are many vibration modes of the vibrating screen, the most common of which are circular vibrating screen, linear vibrating screen, and inclined vibrating screen.

Material movement: The material enters the screen box from the feed inlet, and the vibration causes the surface of the material to undergo complex movements such as jumping, sliding or rolling. Particles with larger particle sizes cannot pass through the screen due to inertia and remain on the screen.

Screening process: The effect of screening depends on many factors, including the amplitude and frequency of vibration, the aperture of the screen, the properties of the material, etc. Particles smaller than the screen hole pass through the screen and fall into the lower screen surface or the discharge port, while particles larger than the screen hole continue to move forward until they are discharged from the discharge port.

Stratification and separation: Multi-layer screens can perform multi-level screening at the same time, and materials of different particle sizes are separated layer by layer. They are usually divided into multiple specifications and collected in order from large to small or from small to large particle sizes.

Discharge: The screened materials are discharged from different discharge ports. Large particles will remain on the screen surface and eventually be discharged through vibration, while the screened fine particles are collected or further processed through other paths.

Main features of vibrating screen

Multi-layer high-efficiency screening: It can be configured with multi-layer screens, adopts circular motion trajectory, and performs multi-stage screening at the same time to meet different particle size requirements and high screening efficiency.

Stable vibration and simple structure: It adopts advanced vibrators, with stable vibration, low noise, and reduced wear on equipment. Compact design, easy installation and maintenance, and reliable operation.

High screening accuracy and large processing capacity: The screen aperture is precise, the screening accuracy is high, and materials of different particle sizes can be effectively separated. The screen surface area is large, the processing capacity is strong, and it is suitable for large-scale production needs.

Strong durability and wide applicability: The screen and screen frame are made of wear-resistant materials, with long service life and reduced replacement frequency. It is suitable for screening of various dry and wet materials with strong adaptability.

Automated control, environmental protection and energy saving: It can be integrated with the automation system to achieve remote control and monitoring and improve production efficiency. The sealing design prevents dust from spilling out, meets environmental protection requirements, and has low energy consumption.

Application of vibrating screens

Mining industry: Vibrating screens are used in mining to screen materials such as ore, coal, limestone, etc. to ensure the quality and purity of the materials.

Construction industry: Screening of sand, gravel, cement, concrete aggregates, etc. to ensure the quality and uniformity of materials.

Chemical industry: Screening of chemical raw materials such as fertilizers, plastic particles, rubber particles. In addition, vibrating screens are also commonly used to screen chemicals, coatings, paints, pigments and other materials to ensure the quality and purity of materials.

Metallurgical industry: Mainly used for screening, grading, and pretreatment of metal powders, alloy particles, metallurgical raw materials, etc.

Environmental protection industry: Vibrating screens also play an important role in processing domestic garbage, industrial waste, sludge, etc., recycling and sorting resources, and participating in the screening and separation process of various substances.

Author:[Xingaonai]

Article Title: what is vibrating screen?how does a vibrating screen work?

Reprint URL: https://www.xgncrusher.com/Industralnews/what-is-vibrating-screen-how-does-a-vibrating-screen-work.html